Problems Laminated Glass

This guidance note has been produced to raise awareness of the effect of edge delamination of laminated glass.

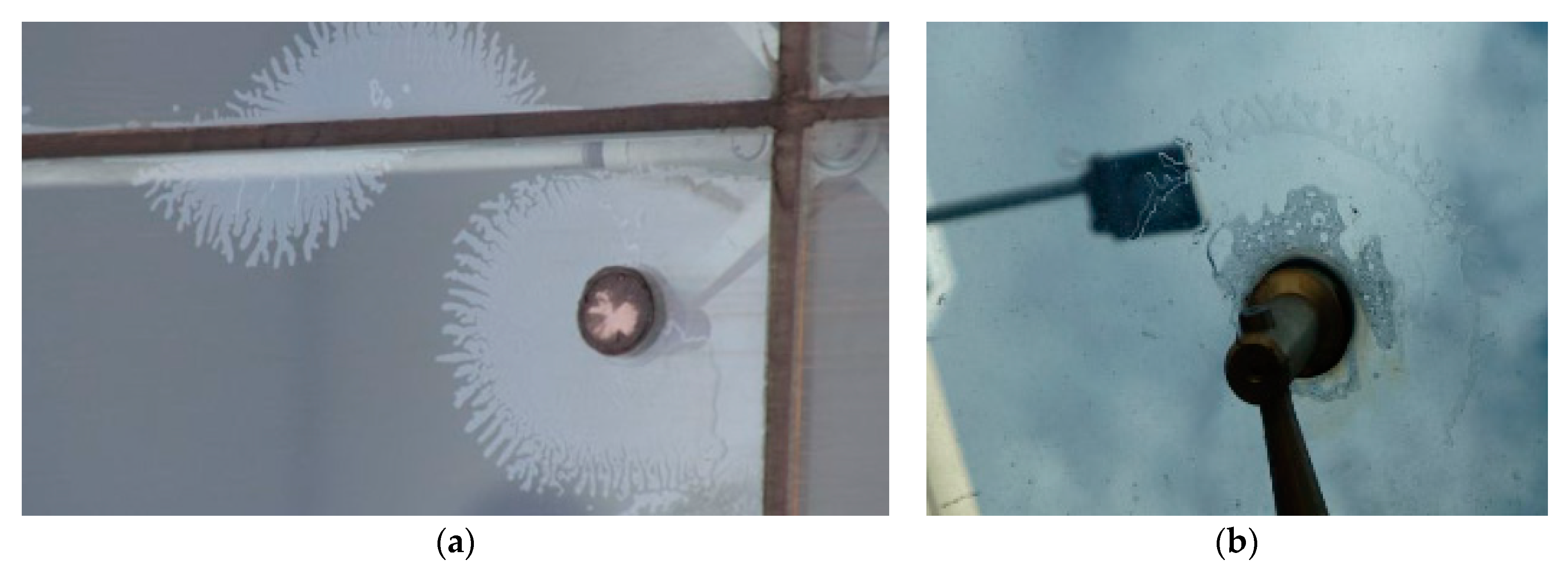

Problems laminated glass. Heating is the most typical stage of glass tempering. Material defects such as edge delamination will reduce this bond and reduce the blast resistance of the laminated glass. The key to avoiding glass delamination problems in your exterior glass balustrade installation is to create water drainage. Bad planity of the glass panes heat treated toughened or strengthened glass.

Typical causes of problems in laminated glass. Most shower enclosures use tempered glass but more often than in the past laminated glass is being used in some shower enclosures because it doesn t shatter into the tiny pieces. Laminated glass is safety glass because if broken the glass stays bonded to the plastic sheet that is between two separate lites of glass. Quality of tempered glass is very much influenced by the heating process used in the furnace.

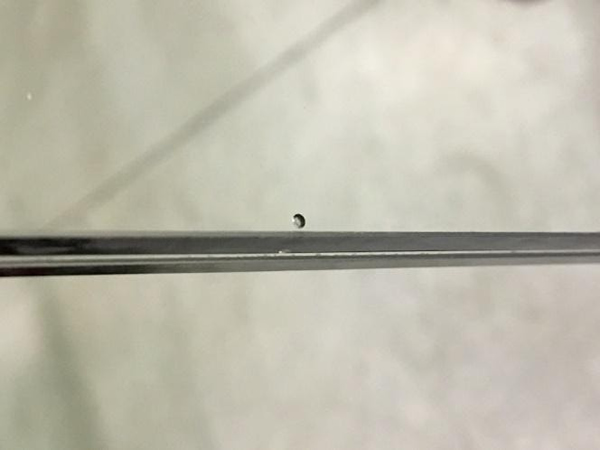

Of laminated glass in buildings there is concern with some architects on the potential for serious delamination issues with laminated glass. Poor processing in general like clamping wrong settings of the nip roller line autoclave etc. Non uniform heating causes deformation of the glass in the quenching process. Safety glass is glass with additional safety features that make it less likely to break or less likely to pose a threat when broken.

Most prominent of such problems is de lamination. A lot depend on this stage to bring out the product of high standard. Between the glass and the interlayer are crucial to ensure that the laminated glass is retained in position. High moisture content of the pvb due to wrong processing or storage.

Laminated glass is made by pasting pvb polyvinyl butyral resin glue film between two or more pieces of glass sheet then heating pressing and bonding them together to create flat or curved compound glass product. In building decorative materials 2011. Bad de airing process residual air in the laminate. In my previous post on laminated glass basics i had mentioned about the clean facility requirement for lamination process.

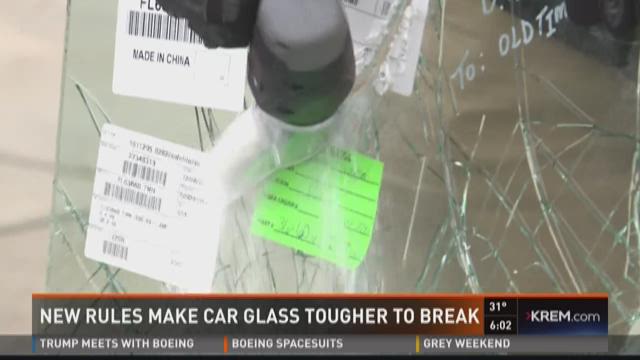

The only problem is that it s extremely difficult to break when it needs to be broken. As a result emergency response teams had to develop new training programs and find suitable tools to overcome this challenge. It can prove life saving in many common situations. With laminated glass in the unlikely event that one pane of glass breaks the glass shards will largely remain stuck to the interlayer avoiding further damage and potential injury resulting from displaced broken glass.

There are major defects happening with laminated glass if the process is not executed properly. The glass sheet for making laminated glass can be ordinary glass float glass tempered glass colored glass heat. Laminated glass is clearly beneficial to driver safety. Typical problems occurring during the heating process.

This happens mainly due to the poor bonding between the glass and pvb sheet.