Problems With Floor Screed

It may be applied onto either a solid in situ concrete ground floor slab or onto a precast concrete floor unit.

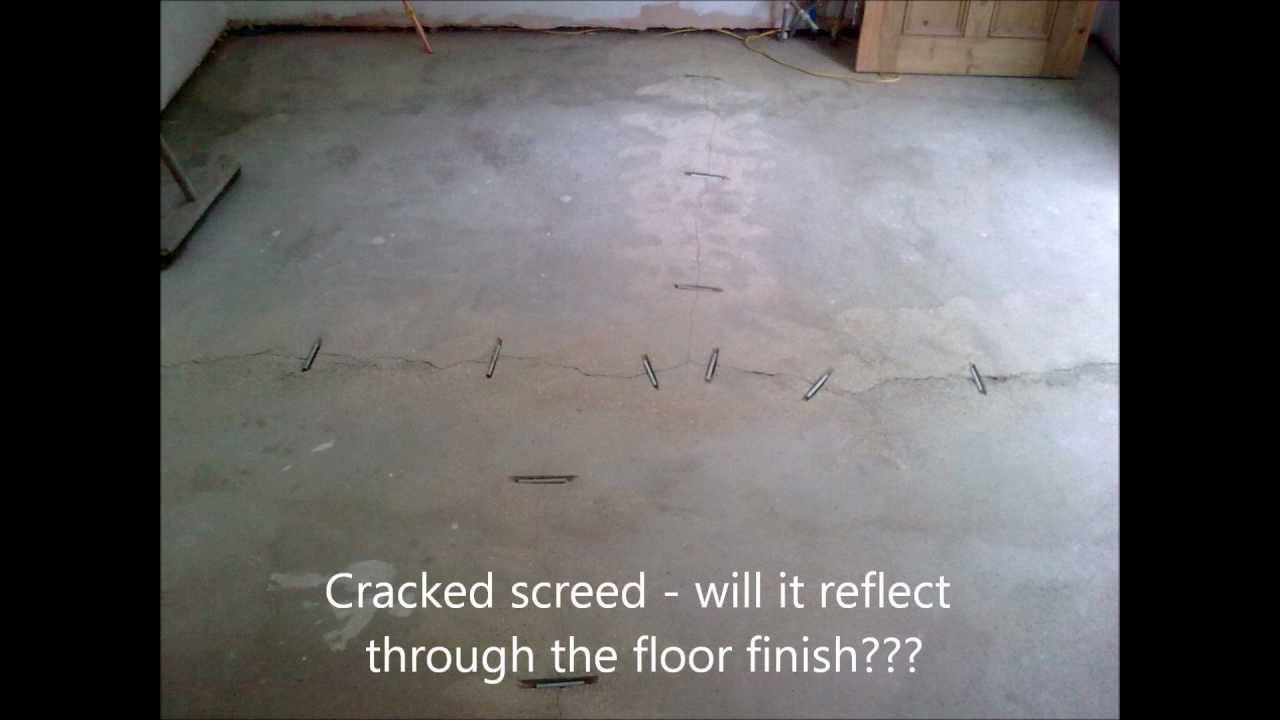

Problems with floor screed. However the repair will be visible this isn t a problem if the screed is simply being used to level the floor prior to applying a finish but if you re intending to stain the screed and leave it exposed then this could be a consideration. Assess and prepare floor. Recommended floor screed based on the type of screed and construction condition. With any screed problem we need to find out why your floor needs a screed repair in the first place and to treat the cause not just the symptom of why the screed has been damaged.

This will provide a dense surface to tile onto and will aid drying. Recommended floor screed thickness based on the type of the screed floor and the construction conditions are provided in table 1. This is useful for applications such as floors that need to slope to a drain or internal ramps. On a job that s had anhydrite screed pumped in using a wolff gm200 moisture meter readings in parts are 99 9 screeds been down since february.

Screed has been directly trafficked and damaged during the construction phase of a project. The cured anhydrite screed will have a layer of laitance that will need to be removed after 2 6 days dependent on brand of screed used. Screeds provide a vital layer in a floor that bonds the finish people see and walk across to the concrete substrate of the building s construction. Screeds are also used to increase the height of a floor.

Ensure the floor is fully dry the residual moisture level should be less than 0 5. There are many proprietary screeds on the market and information about these can be obtained from the manufacturer. We need to look at the possible reasons as to why it could fail and there is quite an extensive list but i think it is important to understand why. The video below gives a great demonstration of tradesmen in a house laying down ground insulation then underfloor heating pipes and then covering both with a screed which is produced with an incredibly.

Floor screeds should have adequate thickness which is based on the screed type and application frequencies. A floor screed is usually a cementitious material made from a 1 3 or 1 4 5 ratio of cement to sharp sand. Screed mix containing less than the required amount of cement. At its deepest it s 150mm what i m stuck with is the builders trying to push on with the job.

Very dry screed mix or poor compaction however over wet screed mixes can lead to shrinkage problems and affect the flatness of the finished screed.