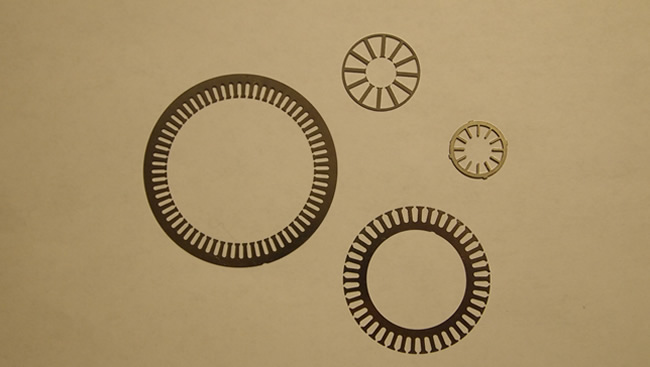

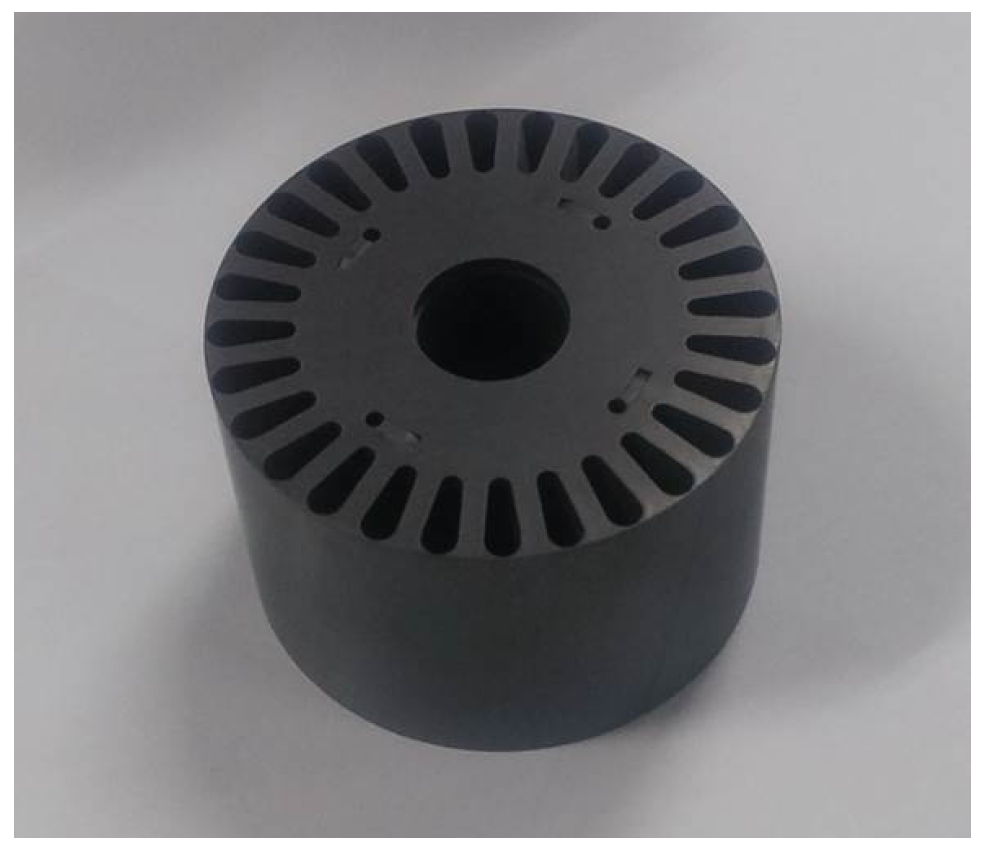

Prototype Motor Laminations

Adding silicon to steel increases its electrical resistance improves the ability of magnetic fields to penetrate it and reduces the steel s hysteresis loss.

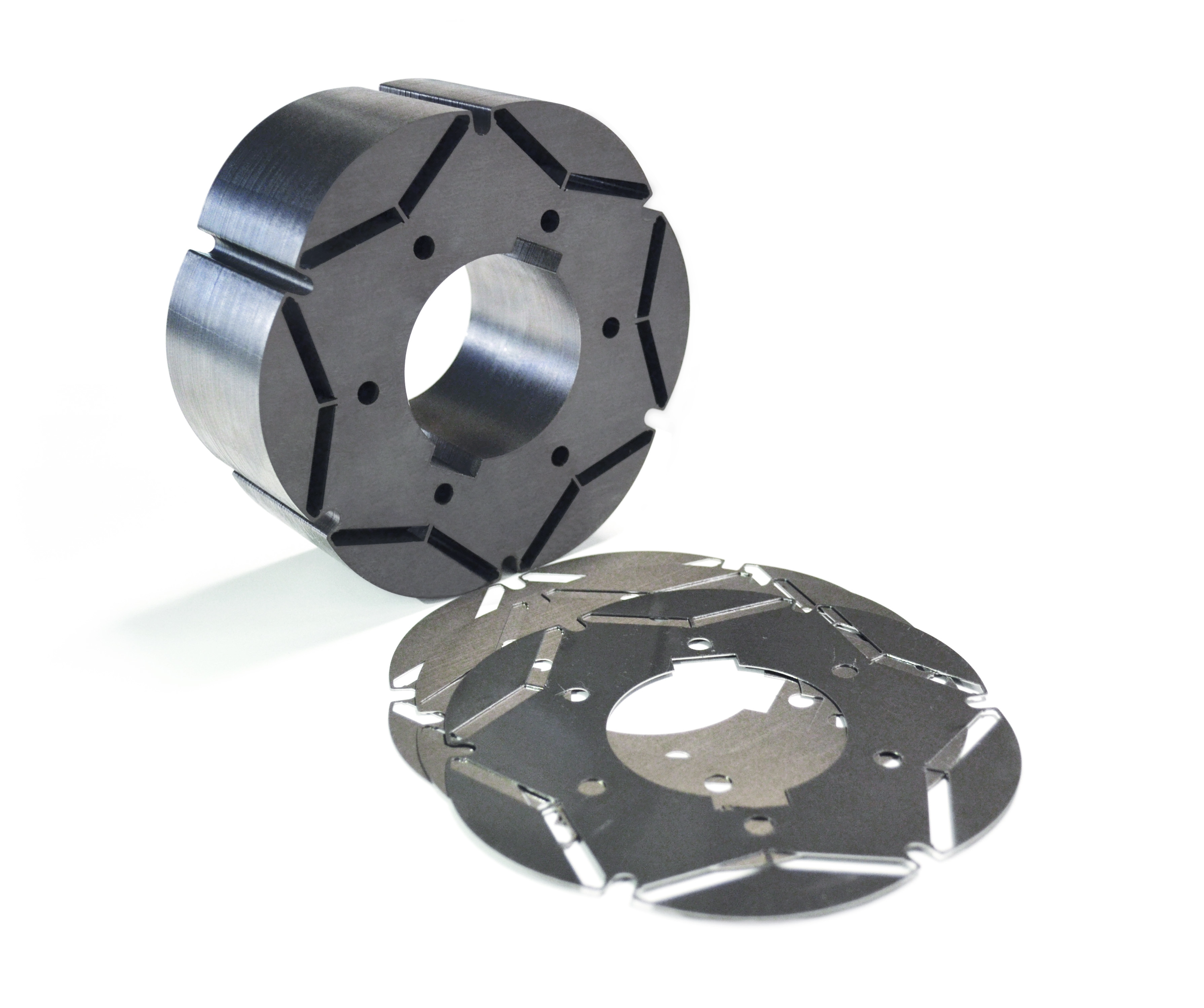

Prototype motor laminations. Motor laminations also referred to as electrical laminations stator laminations rotor laminations pole laminations and segmented stator laminations are profiled from electrical steels stacked then bonded to form the core of transformers or the stator and rotor of electric motors. We have the capability to stack laminations as well. Metal stamping is an innovative process used to create motor laminations for a diverse array of applications. Was established in 2000 and possesses an intimate knowledge of lamination production and design experience our mission is to provide unparalleled standard of excellence in quality and performance while still meeting quick deadlines by utilizing the latest technologies in laser cutting technology.

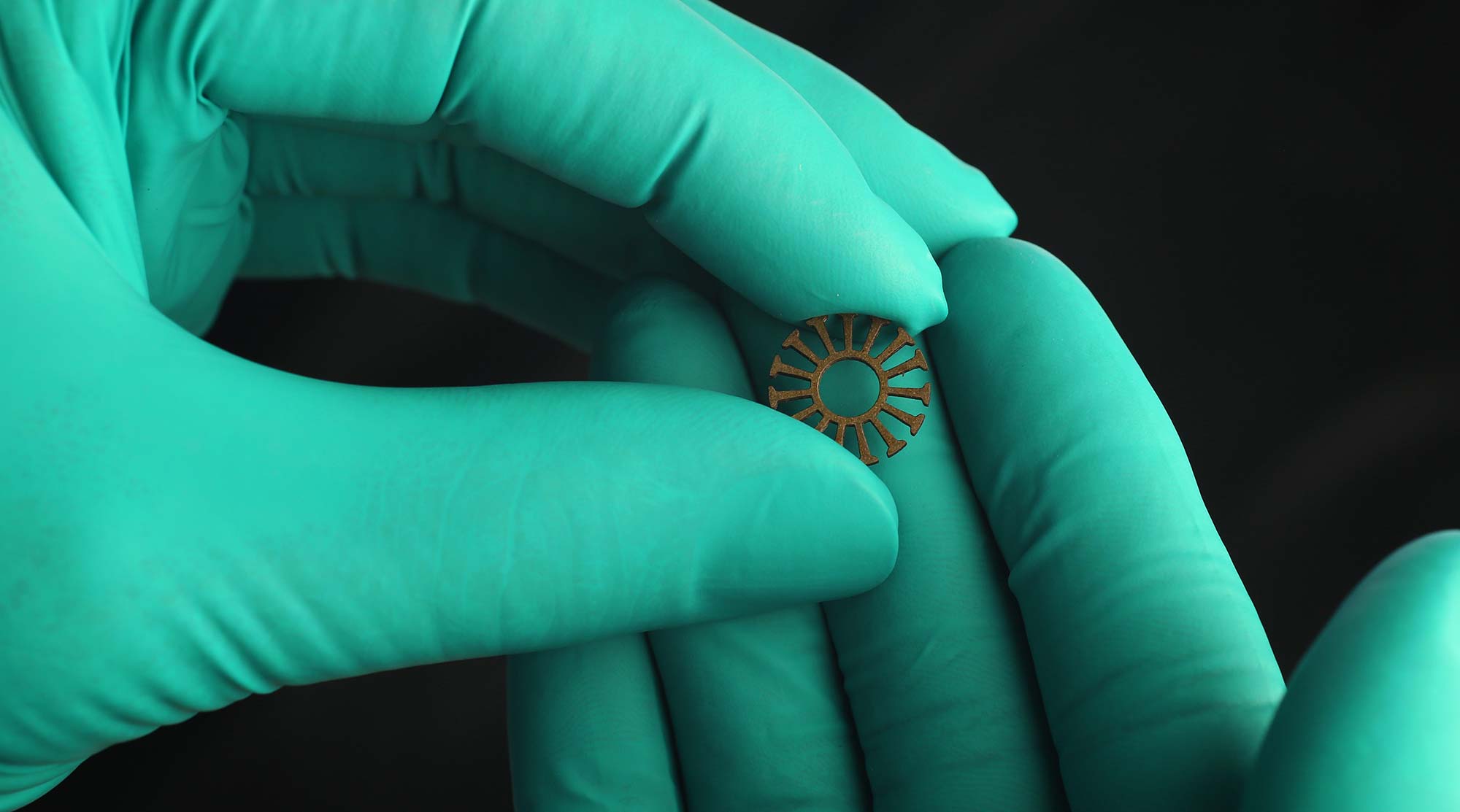

Polaris laser laminations can provide a quick turnaround for design engineers. Electrical steel laminations are supplied in prototype or serial production quantities to micron precision. Custom annealing magnetic testing fluidized bed powder coating. We manufacture and supply dc motor laminations that are made from premium quality materials.

Custom electric motor laminations our electric motor laminations are widely used in motors and generators for aerospace applications electro motion military and food processing applications. Metal stamping offers clients a wide range of customization capabilities as the dies and materials used for this process can be designed to customer specifications. We effectively communicate your project status through every step of the prototype cycle. Silicon steel also known as electrical steel is steel with silicon added to it.

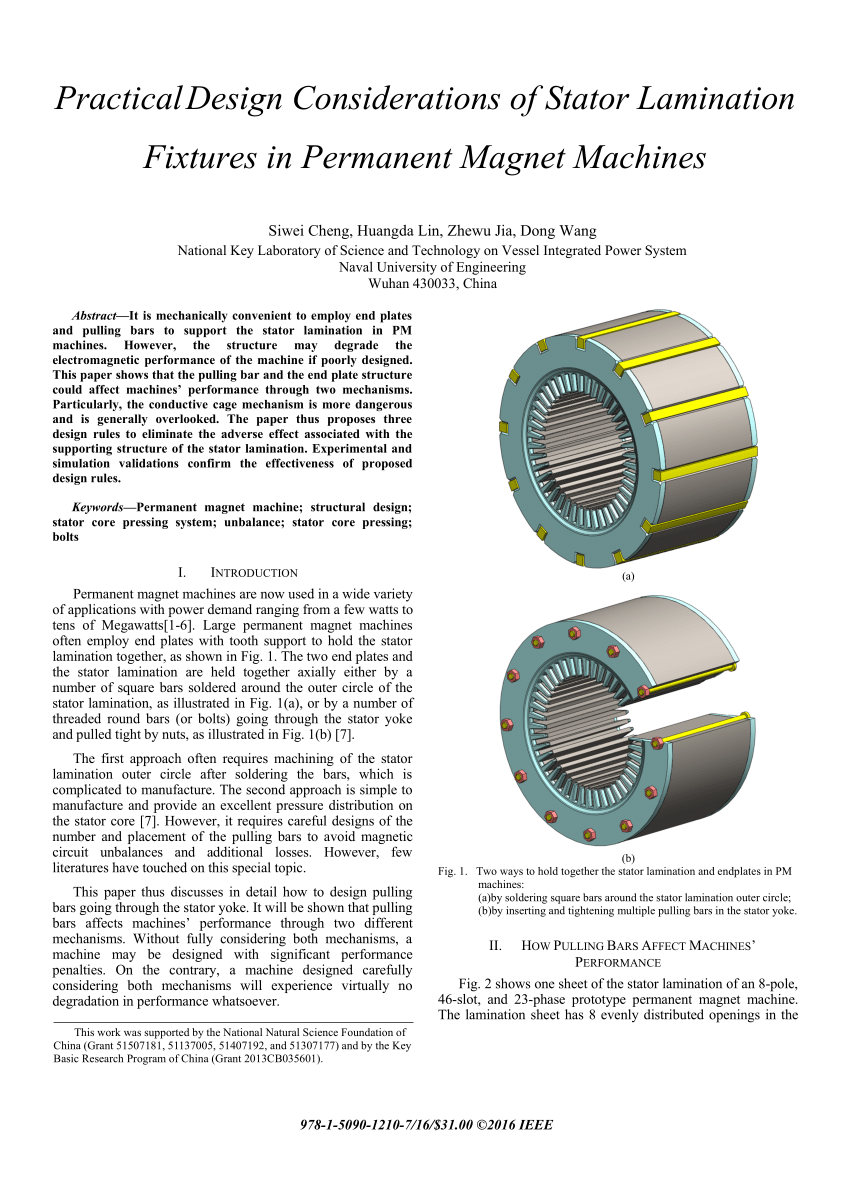

As9100 d iso 9001 2015 registered. Modeling a virtual prototype of stator core lamination assembly device 34 lower lamination pickup table and upper lamination pickup table. We can provide welded stacks or bonded stacks. Our manufacturing operations are designed for maintaining fast turn around and expedited delivery.

Photo etching uses. Motor laminations are created by using electrical steel laminations. Prototype to volume fast. The movement of the vertical slide was driven by electrical servo motor that was linked to robot and caused up and down movement of the horizontal base plate on which the robot was mounted.

We manufacture laminations and lamination segments that range from 0 5 to 36 in diameter. Medium volume and prototype precision laminations and assemblies for motors transformers and generators.