Quarter Sawn Hardwood Lumber Is Cut By The Same Method Used To Produce

For instance tables chairs and other furniture legs benefit greatly from having all exposed sides with the same linear appearance.

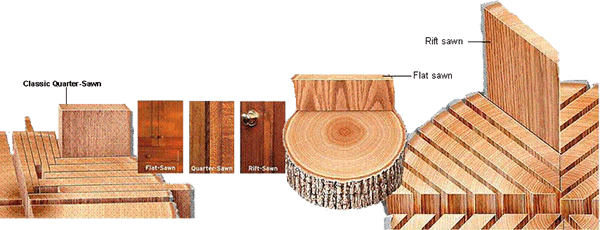

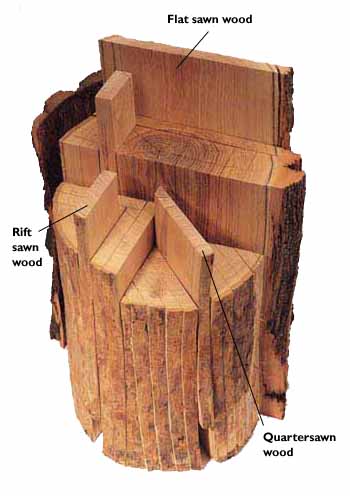

Quarter sawn hardwood lumber is cut by the same method used to produce. Each type of lumber is dependent on how the log is oriented and cut at the sawmill. Reduces shrinking and swelling in hardwood lumber width. By definition quarter sawn lumber is the angle that the annular growth rings intersect the face of the board. Rift sawn lumber you can think of rift sawn lumber or flooring as being cut like a pie is.

Both methods produce some boards with 90 degree grain referenced from the face plane. With these methods the rift method seems to produce more of the 90 degree grain which is what i call quarter sawn wood. This method of quarter sawing does leave some waste but much less than rift sawn lumber. The result is a particular orientation of the growth rings on the end grain of the board and is what defines the type of lumber.

Benefits of quarter sawing. To mill quarter sawn wood each log is sawed at a radial angle into four quarters. When lumber is cut from logs it is typically cut in one of three ways. The result is a particular orientation of the growth rings on the end grain of the board and is what defines the type of lumber.

It is a method used to saw a piece of timber to produce a piece of lumber that has certain desirable characteristics. However there is little agreement what exactly that angle is. At the sawmill each log is sawed at a radial angle into four quarters hence the name then each quarter is plain sawn. One of those characteristics is the large flaking pattern found in white oak quercus alba that has been quarter.

Rift sawn lumber milling is more labor intensive than both plain and quarter sawn lumber. Quarter sawn rift sawn or plain sawn. Then each quarter is plain sawn. Quarter sawn oak as well as domestic cherry and maple show higher luster and also a dramatic amount of surface flecking also known as ribbons which makes for a gorgeous flooring choice.

All of those terms are used to describe what is technically known as quarter sawn or quarter cut oak. More expensive than plain sawn material. Quarter sawn lumber quarter sawn oak hardwood. Most define it as between 60 90 degrees although others define it as between 75 90 degrees or 45 90 degrees.

Quarter sawn wood is more expensive because it is more labor intensive to produce and the manufacturing process produces more waste than plain sawn lumber. Quarter sawn rift sawn or plain sawn. Rift sawn wood is used for applications that require straight lined grain through and through. Each type of lumber is dependent on how the log is oriented and cut at the sawmill.

The type of cut also determines the figure in a piece of wood and the.