Slip Casting Ceramics Definition

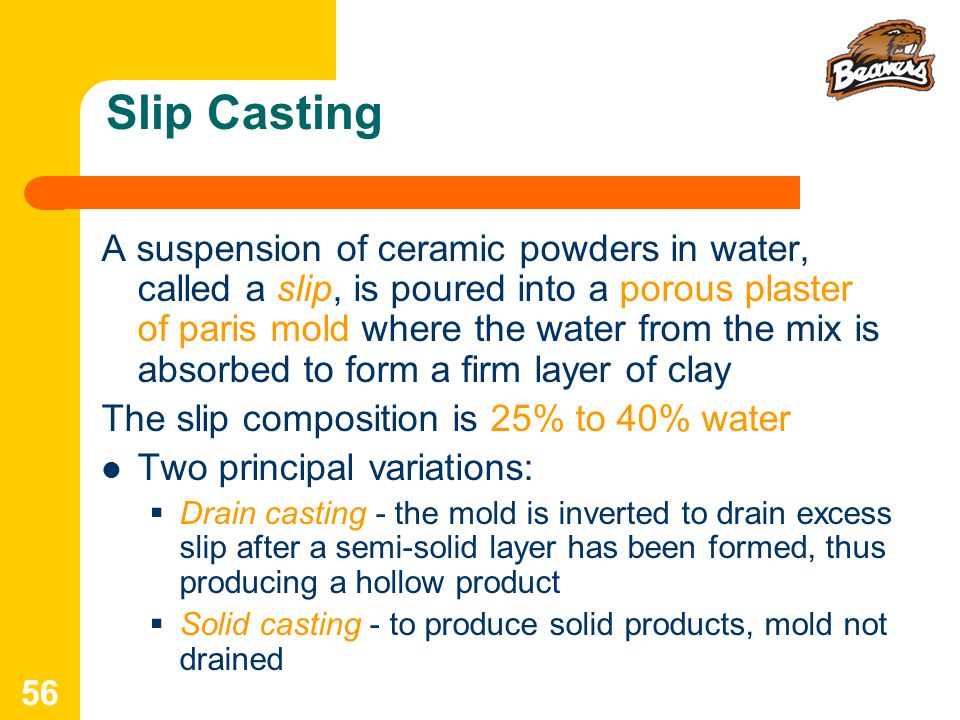

This happens because the mold absorbs the water from the slip through its pores collecting the ceramic particles against the mold.

Slip casting ceramics definition. This has been extremely important for several centuries and secondly to protect or decorate the pottery which is. The water in the slip is drawn out into the walls of the plaster mould leaving an inside layer of solid clay which hardens quickly. Firstly to form the basic shape by slipcasting with moulds. It has many uses in the production of pottery and other ceramic wares.

Slip casting definition a pottery making process in which partially liquefied clay is poured into a plaster mold. Slipcasting or slip casting is a ceramic forming technique for pottery and other ceramics especially for shapes not easily made on a wheel in slipcasting a liquid clay body slip usually mixed in a blunger is poured into plaster moulds and allowed to form a layer the cast on the inside walls of the mould. This pottery method uses an absorbent plaster mold. The process usually takes at least 24 hours per piece.

Slip casting is liquified clay poured into a plaster mold the ratios are roughly 75 percent clay body to 25 percent water. A slip is a liquid mixture or slurry of clay and or other materials suspended in water. 1 teacher instructions ceramic processing. The slip is poured into the mold and the water is absorbed leaving a layer of clay deposited from the slip.

A different approach to the forming of clay based ceramics is taken in slip casting of whiteware as shown in figure 1. Slip casting definition is the process of forming ceramic ware by pouring slip into usually plaster molds. Slip is just a liquid mixture of clay or a liquefied suspension of clay particles in the water and is generally a little thinner than a slurry. There are many forming techniques to make ceramics but one example is slipcasting this is where slip or liquid clay is poured into a plaster mould.

In pottery the two most important uses of slip are. Historically ceramic materials in the form of clay figurines and pots were the first man made materials over 10 000 years ago and maybe even as long as 25 000. Students will learn the fundamentals of slip casting and be able to think critically about why slip casting is used.