Slip Casting Method Of Processing Ceramics

Common forming methods include.

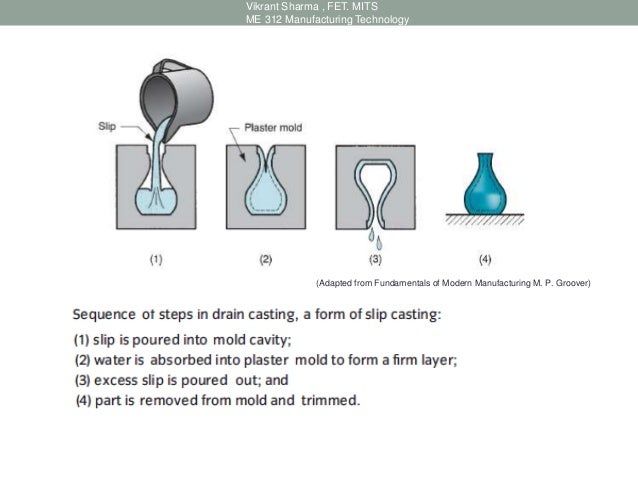

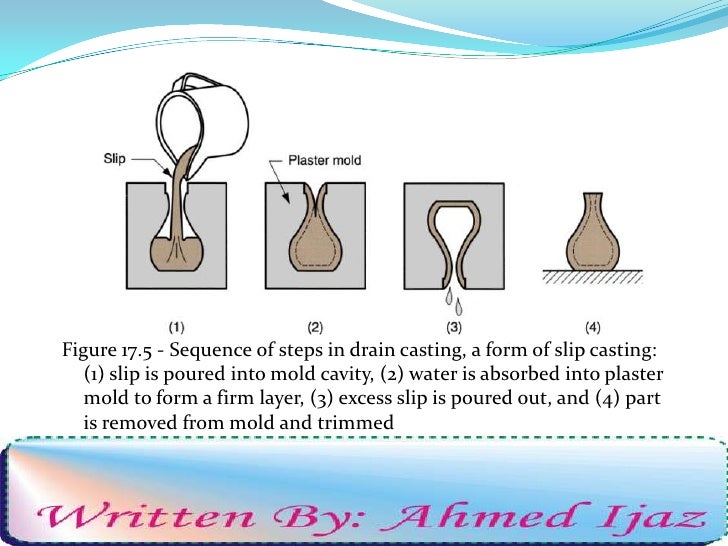

Slip casting method of processing ceramics. First the slip is prepared by mixing the ceramic powder with a liquid. The slip casting process is illustrated below in figure 1. Slip is basically just really runny clay that can be poured as a liquid. Carefully pour your slip into the cavity of the mold and the plaster of paris mold will start to absorb water from the clay and the drying process of the clay will begin.

Historically ceramic materials in the form of clay figurines and pots were the first man made materials over 10 000 years ago and maybe even as long as 25 000. Students will learn the fundamentals of slip casting and be able to think critically about why slip casting is used. This tutorial is demonstrating how to slip cast porcelain in an already existing plas. Slip casting is the process of filling the molds with slip which is the liquid clay allowing it to solidify and after a while forming a layer called the cast inside of the mold s walls.

In today s video an excerpt from his video layers of color andrew shares how he uses a turkey baster to add an organic colored pattern to a slip cast. Once the clay has started to dry to a suitable thickness the timing will depend on the size of the mold but for a medium small mold 10 minutes should do then you can pour. In fundamentals of mold making and slipcasting guy michael davis leads you step by step through the entire mold making and slip casting process. 1 teacher instructions ceramic processing.

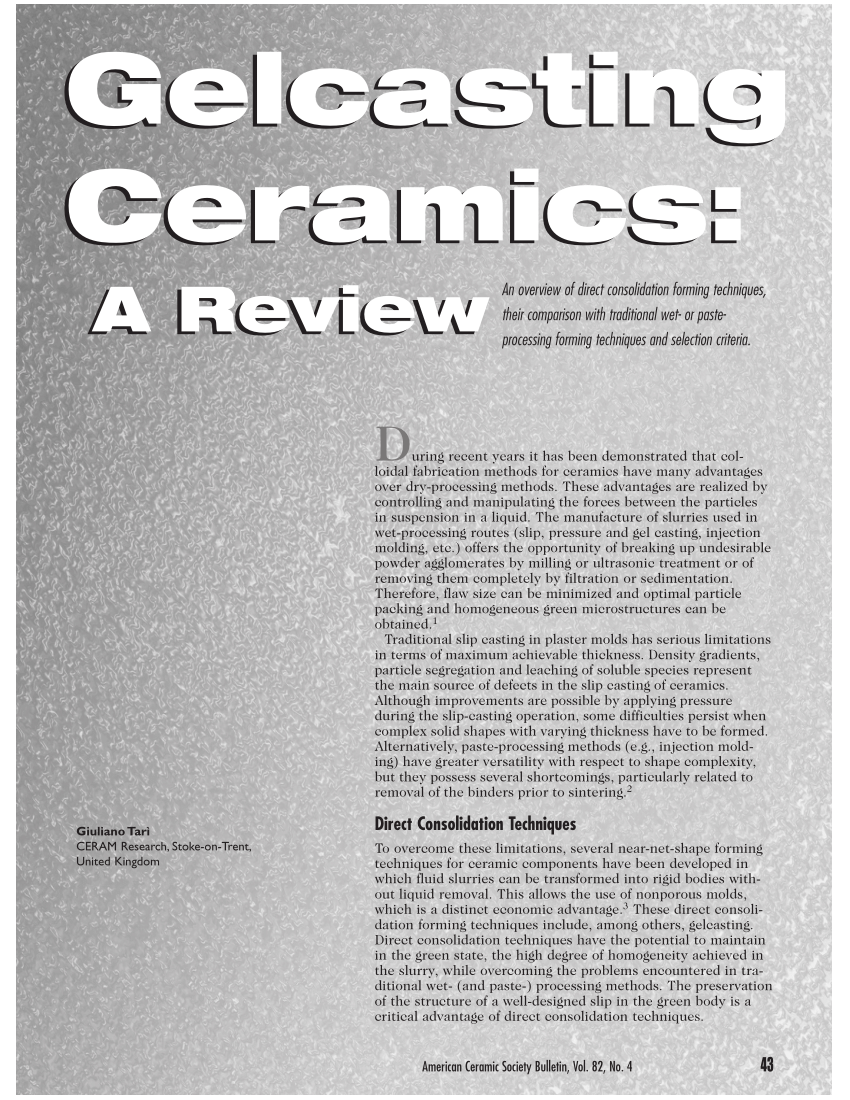

Pressing slip casting tape casting injection moulding hp is mainly for densification of ceramics increases the rate of sintering by. The process usually takes at least 24 hours per piece. Slip casting is a unique and fun process that involves using a ceramic mold and clay slip to case unique and interesting ceramic pieces that you can then fire in a kiln and decorate however you choose with glazes. Schematic showing the steps used in slip casting.

This is a step by step tutorial on how to slip cast. Ceramic mold making techniques learn to make and use bisque molds and plaster molds plus get casting slip recipes when you download this freebie ceramic mold making techniques. This happens because the mold absorbs the water from the slip through its pores collecting the ceramic particles against the mold. Andrew gilliatt adds a whole new level of fun to the slip casting process by using multiple colors of casting slip.

Slip casting ceramics is a forming technique that has endless potential. Reducing the time for sinter ing reducing temperature of sintering slip casting clay product a slip is a suspension of clay and or other nonplastic materials in water.