Vinyl Acetate Monomer Process Pdf

More importantly the plant model provides a new benchmark problem.

Vinyl acetate monomer process pdf. Firstly combining their separate feeds in a mixer to create a mixture creates a mixture of oxygen ethylene and acetic acid. Vinyl acetate monomer october 2012 vinyl acetate production from the acetoxylation of ethylene was developed and commercialized starting with the liquid phase process. Vinyl acetate monomer vam production and manufacturing process. Other applications are coatings for textile and paper industries laminated.

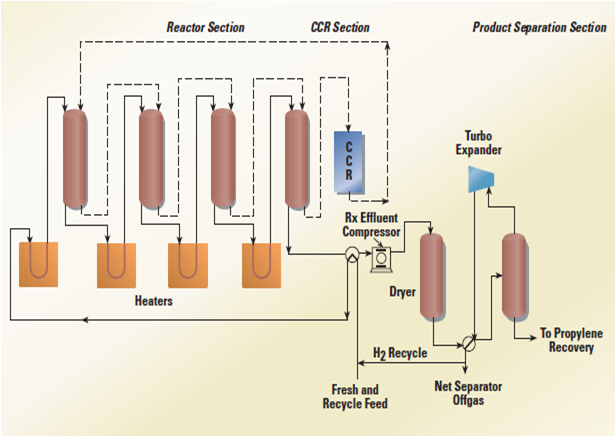

Vinyl acetate monomer process 287 10 10 1 basis of design the vinyl acetate monomer vam is large scale commodity chemical mostly used in manufacturing polyvinyl acetate the basic ingredient in water soluble acrylic paints. Vinyl acetate c4h6o2 cid 7904 structure chemical names physical and chemical properties classification patents literature biological activities safety. The users can investigate. 1 introduction the production of vinyl acetate from ethylene is an 11 step process which utilises the process of a stoichiometric reactor distillation column flash phase separators and a decanter.

Therefore the study of vinyl acetate bulk polymerization is of great interest from a process safety point of view even if it is not a commercial wide spread process. Abstract a rigorous dynamic plant model of a vinyl acetate monomer vam production was developed. A simulation of a vinyl acetate monomer vam process design was developed and compared with the work of luyben and tyreus 1998. Two incremental changes were made to the two main control.

Monomers or in premix vessels where a polymerization initiator was dissolved in vinyl acetate monomer previous to its use in the polymerization process. Vinyl acetate is the acetate ester of vinyl alcohol. Acetylene based technology was used first in the commercial production of vam with the gas phase process preferred to the liquid phase reaction. Representative base design control strategy and dynamic simulation of a vinyl acetate monomer process design.

This plant model enables the users to experience realistic plant operation since it reflects the real plant characteristics and practical problems on the basis of experienced practitioners opinions. Since vinyl alcohol is highly unstable with respect to acetaldehyde the preparation of vinyl acetate is more complex than the synthesis of other acetate esters. Ethylene has now become the preferred feedstock with the gas phase route used due problems of corrosion and byproduct. Third complete a plantwide implementation of alternative control strategies for the process using classical and more.