Vinyl Acetate Production Catalyst

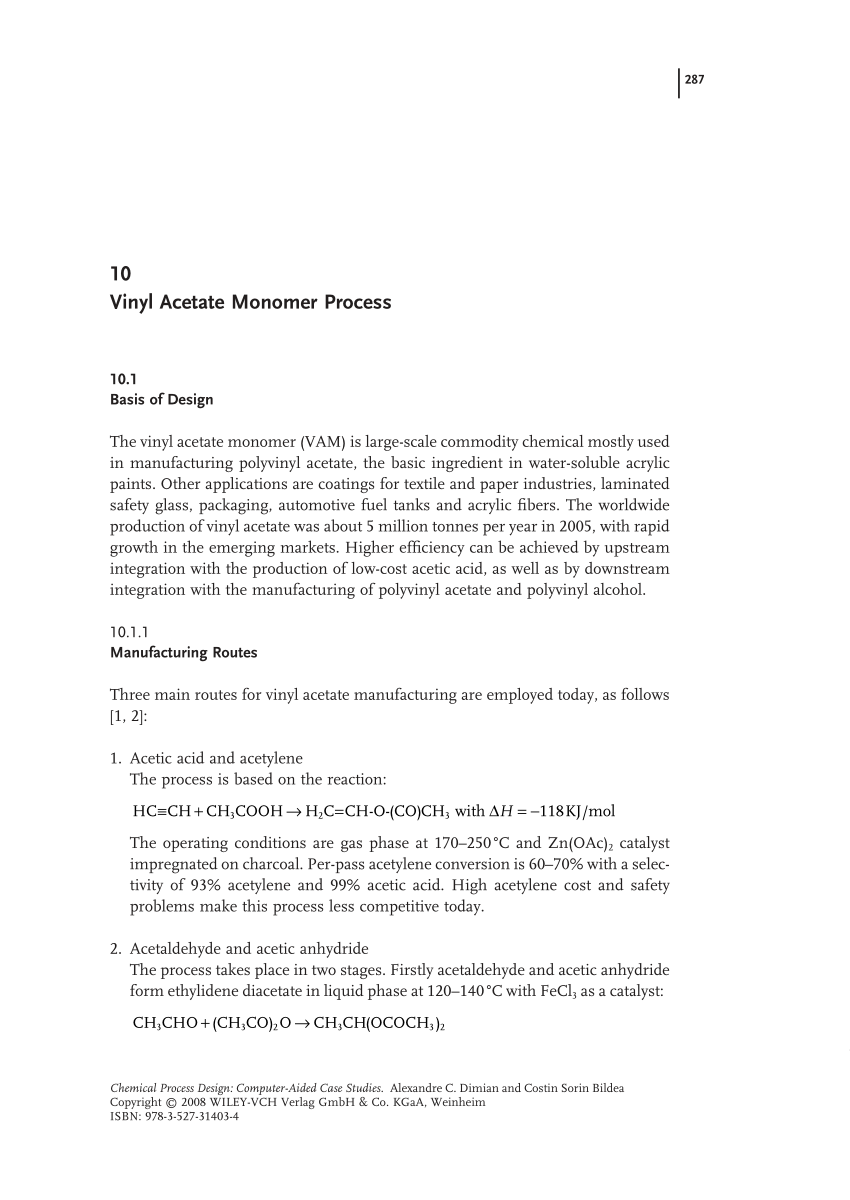

Vinyl acetate monomer vam is an important chemical intermediate used in manufacturing of coatings adhesives and textiles.

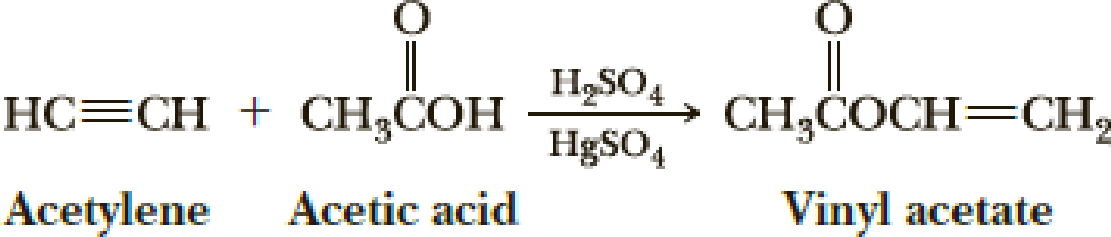

Vinyl acetate production catalyst. A worldwide annual demand of over four million metric tons of. Vinyl acetate is the acetate ester of vinyl alcohol. Vinyl acetate ch 2 cho 2 cch 3 is prepared from ethylene by reaction with oxygen and acetic acid over a palladium catalyst under the action of free radical initiators vinyl acetate monomers single unit molecules can be linked into long branched polymers large multiple unit molecules in which the structure of the vinyl acetate repeating units is. 5 185 308 describes a shell impregnated catalyst active for the production of vinyl acetate from ethylene acetic acid and an oxygen containing gas the catalyst consisting essentially of 1 a catalyst support having a particle diameter from about 3 to about 7 mm and a pore volume of 0 2 to 1 5 ml per gram 2 palladium and.

The largest user of acetic acid is the vinyl acetate monomer vam manufacturing industry. Since vinyl alcohol is highly unstable with respect to acetaldehyde the preparation of vinyl acetate is more complex than the synthesis of other acetate esters. Vam is the basis of white glue laminating wallboard and latex paint. A preferred invention palladium gold catalyst provides exceptional improvement of carbon dioxide selectivity in vinyl acetate production.

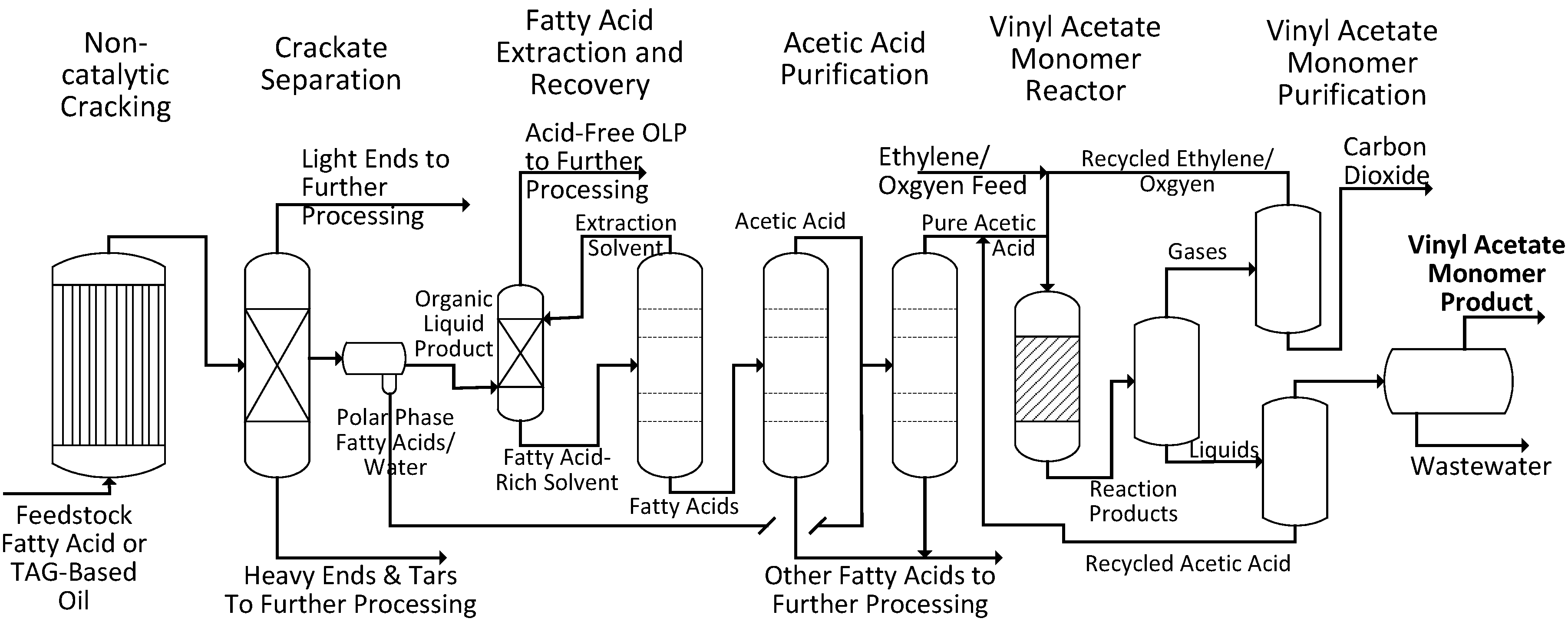

The major route to production of vam is through the reaction of ethylene with oxygen and acetic acid over a bimetallic palladium gold catalyst. All of the reactants employed in the catalyst preparation are potassium salt compounds which are essentially sodium free. A simplified process scheme for the production of vinyl acetate monomer from a fatty acid or triacyl glyceride based oil via non catalytic cracking. Vinyl acetate production by ethane catalytic acetoxylation with acetic acid obtained as intermediate.

The major industrial route involves the reaction of ethylene and acetic acid with oxygen in the presence of a palladium catalyst. Production of vinyl acetate was about 5 million tonnes per year in 2005 with rapid. A bringing gaseous raw material containing ethane as a main component into contact in the first reaction zone with molecular oxygen containing gas in presence of catalyst to obtain the first product stream including acetic acid and ethylene. Alumina or silica supported palladium catalyst in conjunction with gold along with.

This invention provides a supported palladium gold catalyst for vinyl acetate production from ethylene acetic acid and oxygen. Vinyl acetate production from the acetoxylation of ethylene was developed and commercialized starting with the liquid phase process.