Vinyl Acetate Production Process

Vinyl acetate c4h6o2 cid 7904 structure chemical names physical and chemical properties classification patents literature biological activities safety.

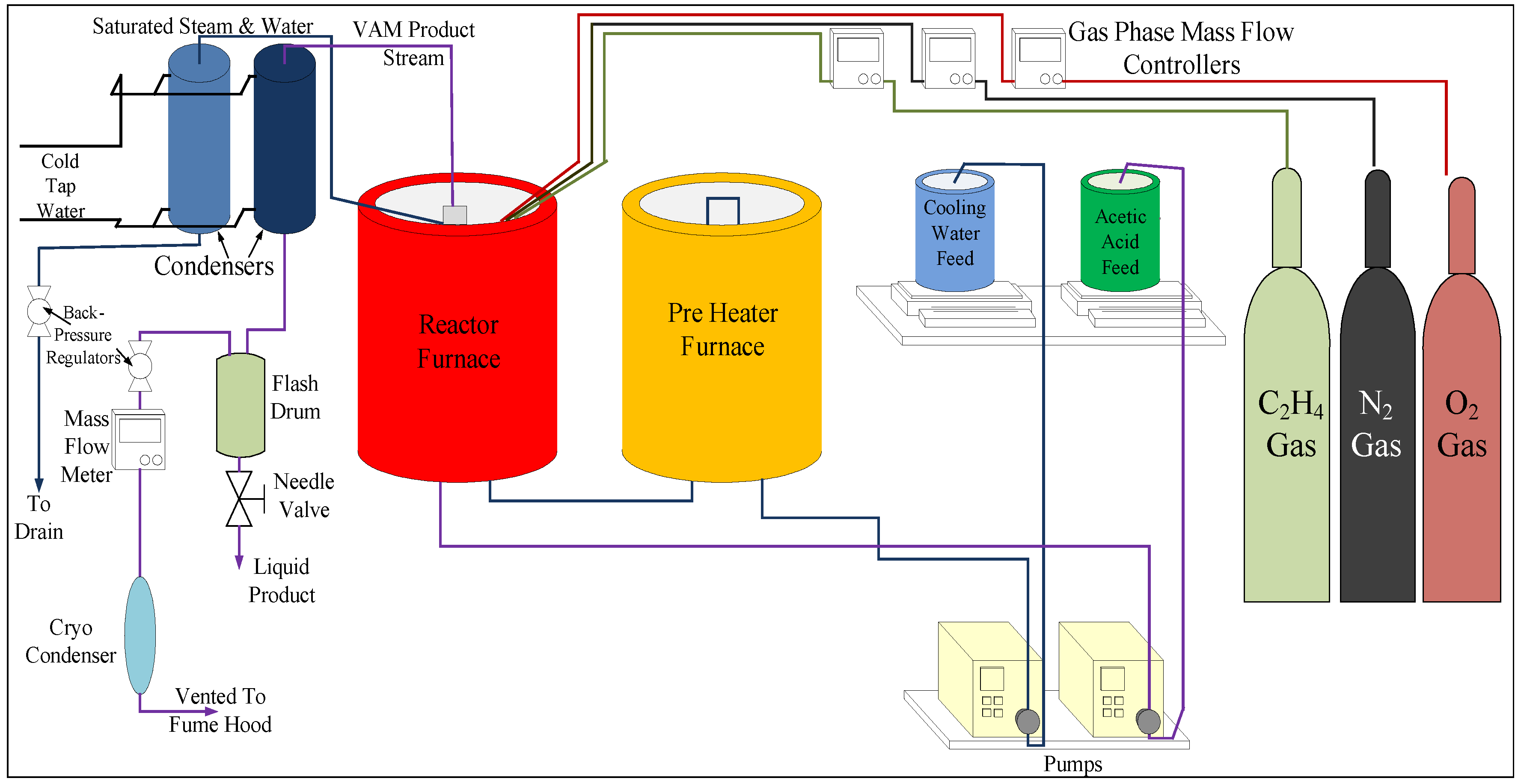

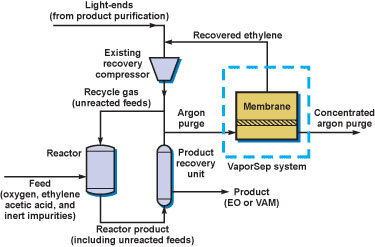

Vinyl acetate production process. Vinyl acetate monomer vam production and manufacturing process acetylene based technology was used first in the commercial production of vam with the gas phase process preferred to the liquid phase reaction. A process for forming vinyl acetate comprising the steps of. This method involves the gas phase addition of acetic acid to acetylene in the presence of metal catalysts. The method comprises reacting ethylene acetic acid and an oxygen containing gas in the presence of a catalyst in a reactor to produce vinyl acetate measuring the concentration of a component.

Vinyl acetate ethylene vae emulsions are based on the copolymerization of vinyl acetate and ethylene in which the vinyl acetate content can range between 60 and 95 percent and the ethylene content ranges between 5 and 40 percent of the total formulation. The following are the primary and side reactions. This process consisted in the reaction of acetylene with acetic anhydride in a catalyzed medium and high temperature to form dietilene diacetate. Vinyl acetate monomer vam production which is based on reacting acetic acid aa with ethylene and oxygen dimian and bildea 2008.

Poly vinyl acetate was discovered in germany in 1912 by fritz klatte. A process is disclosed for the production of vinyl acetate where a mixture of ethylene acetic acid and oxygen is reacted in the presence of a catalyst to produce a product mixture of vinyl. By this route using mercury ii catalysts vinyl acetate was first prepared by fritz klatte in 1912. B calculating a flammability limit of oxygen based on an amount of water in the reacting step.

Vam production process the first available process for the synthesis of vinyl acetate was the acetoxilation of acetylene in gaseous form over a zinc acetate catalyst supported on carbon. The monomer vinyl acetate was first produced on an industrial scale by the addition of acetic acid to acetylene with a mercury i salt but it is now primarily made by palladium catalyzed oxidative addition of acetic acid to ethylene. Pva is a vinyl polymer.