Vinyl Chloride Monomer Production Process

Vinyl chloride also known as vinyl chloride monomer vcm and chloroethene is an organochloride compound.

Vinyl chloride monomer production process. At room temperature vcm is a gas with a sweet ethereal odor but in industrial processes it is most often handled as a liquid melting point 13 c. Pvc is used in a variety of applications. Vinyl chloride monomer vcm production and manufacturing process commercial production of vcm started in the 1920s based on the catalytic hydrochlorination of acetylene but this route suffered from high energy costs and has become obsolete except for china. It is primarily used to manufacture polyvinyl chloride pvc a very stable non flammable lightweight and durable plastic.

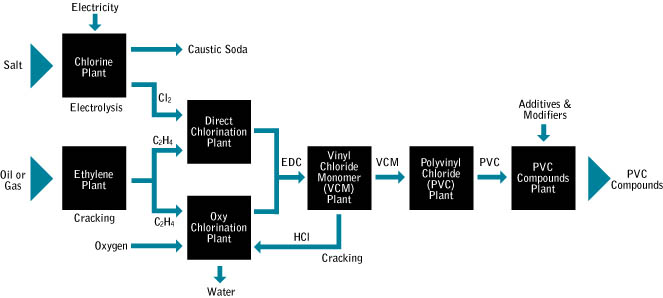

In the direct chlorination as well as in the oxychlorination process ethylene dichloride edc is produced. Chlorine is derived from brine a solution of common salt and water. Vinyl chloride monomer vcm is the key chemical precursor to pvc. Pvc has the advantage of being utilized in conversion and fabrication processes with great flexibility such that end products cover a wide.

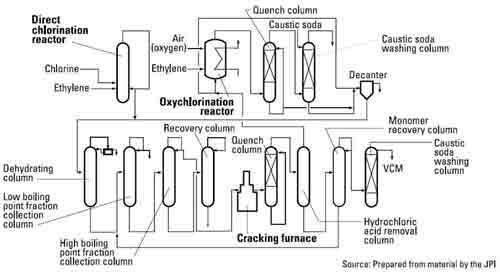

The five main processes used in the production of vinyl chloride monomer vcm are. These processes are shown in figure 1. Refer to the section manufacturing process for more detail. Balanced process for vinyl chloride production no generation of hcl 95 of the world s vcm is produced utilizing the balanced process heavy ends oxy chlorination direct chlorination edc purification edc pyrolysis vcm purification hcl recycle air or o 2.

Vinyl chloride monomer summary vinyl chloride monomer vcm is a colorless flammable gas at room temperature. Its chemical formula is c2h3cl. From its flake or pellet form pvc is sold to companies that heat and mold the pvc into end products such as pvc pipe and bottles. 1 direct chlorination of ethylene to form edc 2 oxychlorination of ethylene to form from recycled hcl and oxygen 3 purification of edc 4 thermal cracking of edc to form vcm and hcl and 5 the purification of vcm.

Today vinyl chloride monomer vcm is produced as a intermediate chemical by the process of either hydrochlorination of acetylene or the dehydrochlorination of ethylene dichloride edc. It is produced commercially by combining a hydrocarbon feedstock namely ethylene obtained by cracking natural gas or petroleum with elemental chlorine. Vcm is used primarily for the production of polyvinyl chloride pvc homopolymer and copolymer resins. Vinyl chloride monomer vcm is one of the world s most important and largest commodity chemicals.

The vinnolit process for the production of vinyl chloride monomer vcm from ethylene and chlorine proceeds via two different routes. Vcm is a major commodity chemical mainly used in the production of the polymer.

.jpg)