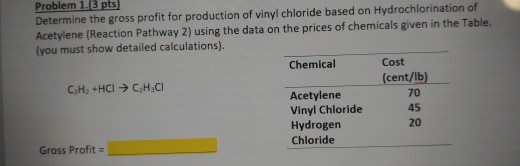

Vinyl Chloride Production From Acetylene

Acetylene dichlorethane vapor and hydrogen chloride gas at a molar ratio of 1 0 3 1 0 0 0 20 are mixed.

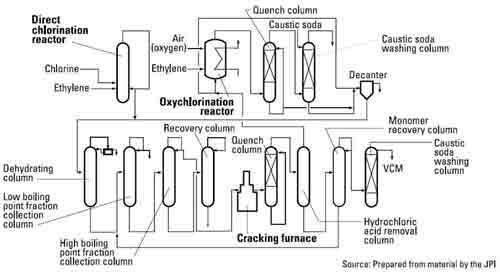

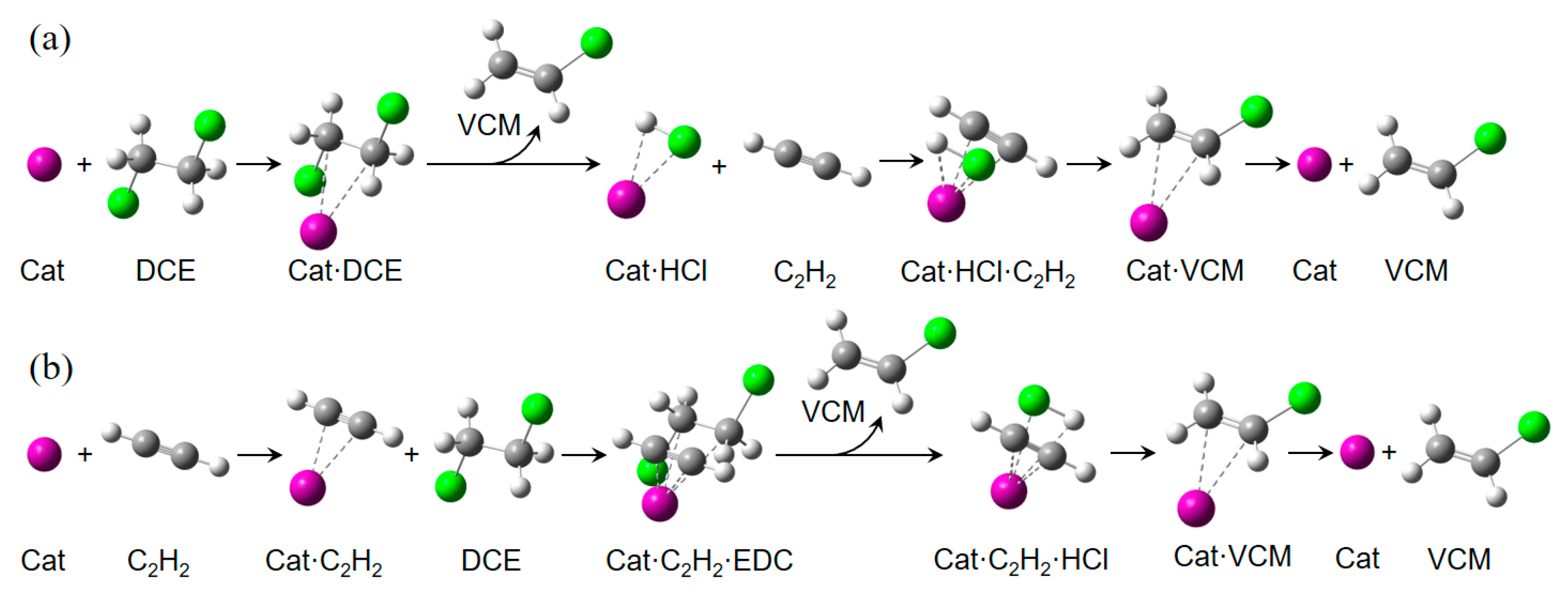

Vinyl chloride production from acetylene. 2 1 vinyl chloride from acetylene the process that produces vinyl chloride from acetylene employs the use of a catalyst. Provided is a method for preparing vinyl chloride with acetylene and dichlorethane for large scale industrial production. The resultant mixed gas is cooled to 30 50 c. Clch 2 ch 2 cl ch 2 chcl hcl the thermal cracking reaction is highly endothermic and is generally carried out in a fired heater.

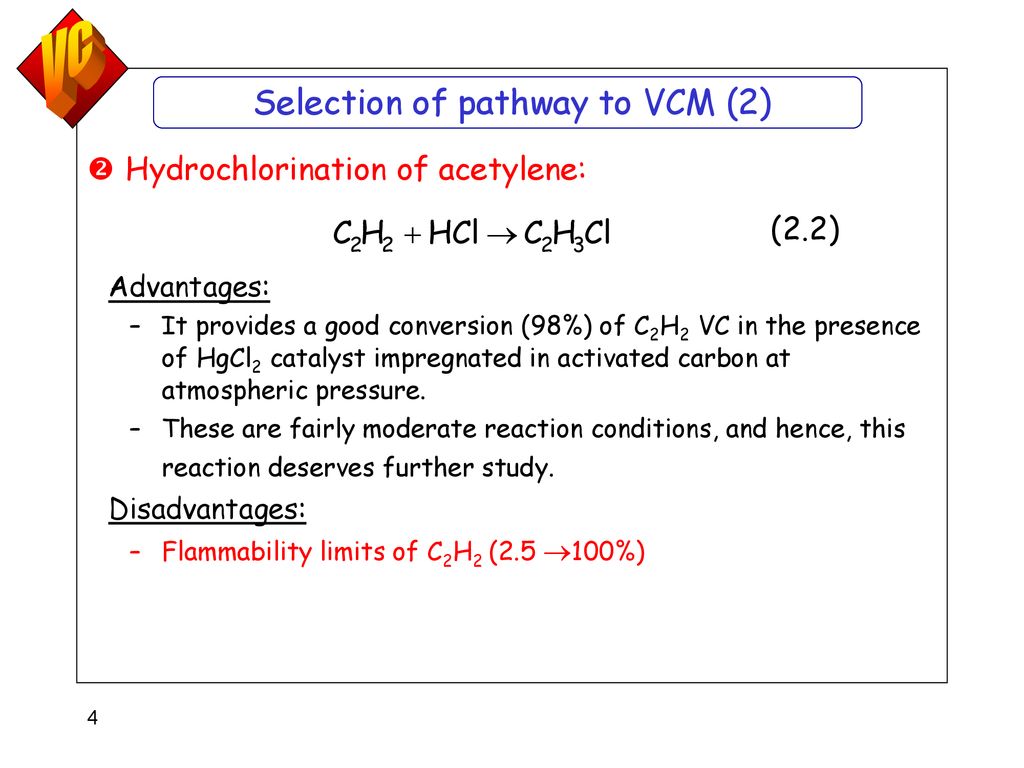

Although largely superseded in many developed countries by processes based on ethene hydrochlorination of acetylene is still an important process for vinyl chloride production in locations where coal based economies remain active. However the vinyl chloride monomer vcm production catalyzed by hgcl 2 faces the difficulties in heat transfer high pollution to environment and health threat to human beings. Most of the time the catalyst used is mercuric chloride deposited on active carbon. To overcome these disadvantages of conventional fixed bed reactor and toxic hgcl 2 catalyst a new cost effective and non mercury catalyst and process are is crucial.

A rate equation which well represented the data was developed from the following postulates. This production method is cheaper than preparing edc from acetylene which is why it has become the major route to vinyl chloride since the late 1950s. Vinyl chloride monomer vcm is a main raw material to synthesize poly vinyl chloride pvc. The raw mixed gas is preheated.