Vinyl Ester Fiberglass Prepreg

High temperature laminates and high temperature ducting.

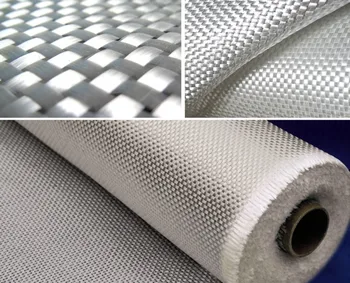

Vinyl ester fiberglass prepreg. 275 f 135 c 300 f 149 c styrene free. Woven prepreg 1 or 2 side coated off white on white. Csm turns transparent only when wet out with polyester or vinyl ester resins which contain a solvent styrene that breaks down the mat that bonds the fibers in place. Abc composite acquired recently prepregs production facilities and rights of gulf composite materials.

Vinyl ester resin is considered to be a hybrid of polyester and epoxy resins meaning its handling characteristics properties and even price generally fall just between the two. The aerospace industry is the greatest consumer of hexcel prepregs for civil aircraft military jets helicopters aero engines or space satellite and launchers. Common reinforcing materials such as fiberglass aramid and carbon fiber fabrics are solution coated using three commercial treaters. Abc composite is co owner of a patented technology developed for converting epoxy vinyl ester resins into prepregs suitable for advanced composite materials.

Woven prepreg 1 or 2 side. Prepreg fabrics for use in manufacturing processes for a wide range of products for aircraft automotive recreation equipment ballistic and other industrial applications are. Vinyl ester is formulated for maximum corrosion resistance to most fuels vapors and chemicals. Hexcel s range of resin formulations for aerospace prepregs includes a wide.

It s heat resistant and blended for durability. Hexply prepregs are reinforced with woven multiaxial and unidirectional ud carbon and glass fibers. With the exception of csm lower weight fiberglass materials turn completely transparent when wet out with epoxy polyester or vinyl ester resin.