Vinyl Sheet Piling Vibratory Hammer

Sheet piling uk ltd have recently purchased an ex hire fleet pve38m vibratory hammer and pve500 model power pack from the leading piling and foundation equipment hire company watson hillhouse ltd.

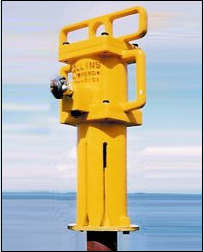

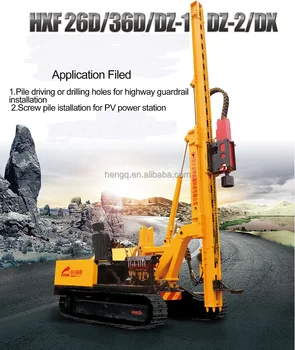

Vinyl sheet piling vibratory hammer. The vibratory hammer is positioned on top of the sheet pile with clamps. August 3rd 2020 new pve38m vibratory hammer purchased. Hpsi 20 vibratory hammer small vibro hammer with hydraulic power pack for use with crane or excavator available for rent or sale. After placing a pile driving frame the sheet piles are driven by a crane arig or excavator mounted vibratory hammer.

Sheet piling can be installed with conventional pile driving equipment vibratory pile hammers air and water jets hand and or machine trenching. This video show shoreguard synthetic sheet pile being driven using a small vibratory hammer. Vibratory pile hammers are widely used because they usually can drive sheet piles faster do not damage the top of the pile and can easily extract piling when necessary. Provided of course the soils are granular a vibratory hammer can drive steel sheet piling far faster than impact hammers.

Manufactured by the world renowned experts in the development and innovation of vibe technology pve develop and build a range of. In cohesive clays and silts drop hammers vibratory plate compactors and backhoe buckets are generally the tools of choice. It produces a sine wave vertical pressure and the energy of the hammer will quickly drive the pile into the soil. Installation tools for vinyl sheet piling are generally dependent on the soils being driven into.

In order to fully protect the piling against damage light equipment with small impact energy is used. This is a small vibratory hammer capable of driving shorter sheet piles both vinyl sheets and steel sheets. Sheet piling uses include seawalls bulkheads or retaining walls dikes shoring flood walls slide walls erosion control structures hazardous soil containment machinery foundations and electric.