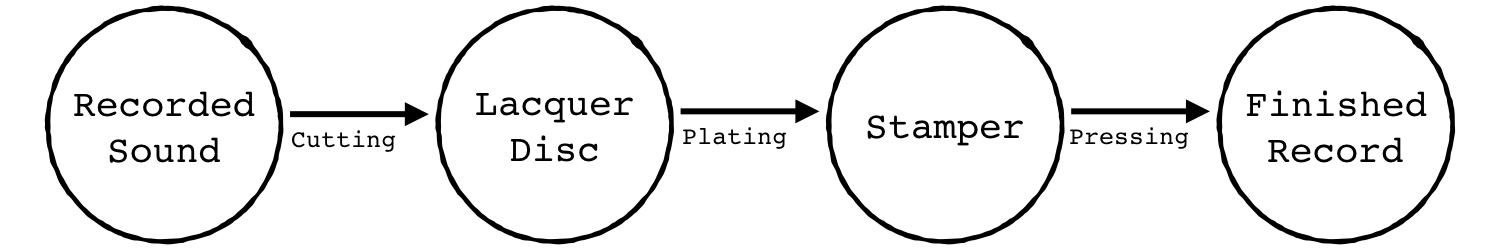

Vinyl Record Production Process

For aficionados that are curious about the process of how vinyl records are made follow along as we go through the steps with help from telegraph mastering bonati masterting and cascade record pressing.

Vinyl record production process. A deeper look into the record making process. There is a quick cooling cycle that solidifies the vinyl and bonds the labels. The vinyl puck is in the middle and when the mold closes it presses the record flat with a label on either side. Please refer to our pricing page for the most current turn time.

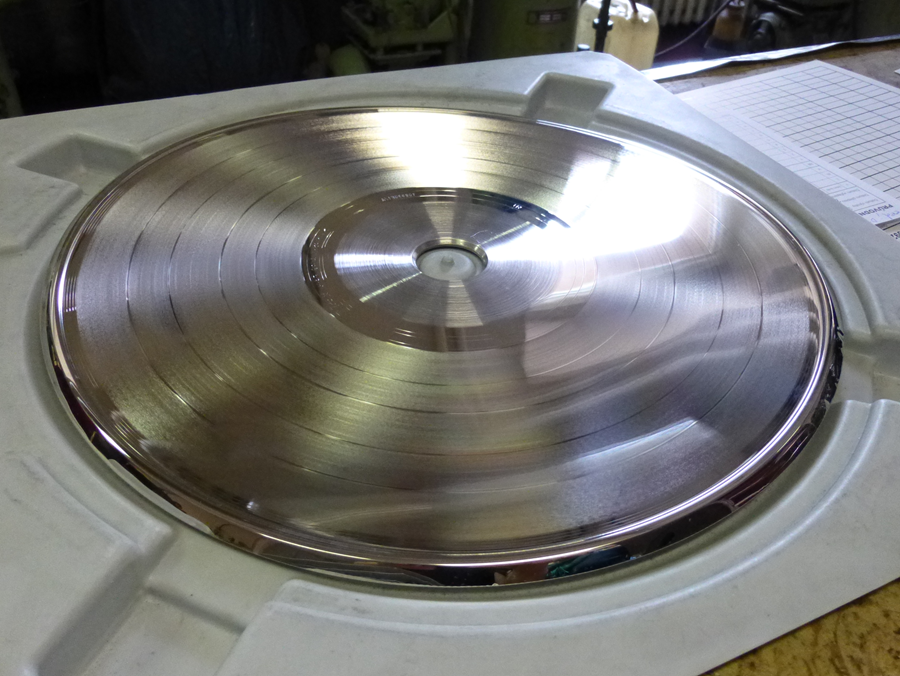

This article is about the production of vinyl records. The discs are then placed on a conveyor belt ready to be coated in a nitrocellulose nitro lacquer. These flat discs are made from an aluminum core which is first sanded down to a smooth finish. Placing the labels on the top and bottom of the biscuit the 2 stampers top side a and bottom side b press down applying 100 tons of pressure at 200 degrees celsius creating the vinyl record.

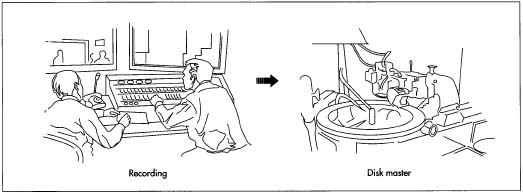

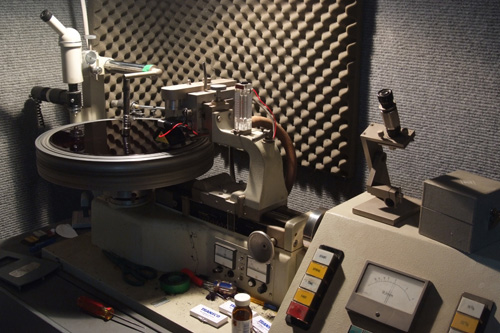

The recent increase in vinyl production means that the wait time for a new record to be pressed has gone from as much as 10 months in 2007 to as little as six weeks today. One stop shop vinyl record manufacturing services. Rollers catch the excess run off lacquer which is re used. The vinyl manufacturing process step 1 manufacturing the master disc.

7 10 or 12 vinyl record pressing full mastering plating color vinyl etched vinyl heavyweight vinyl full color jackets labels stickers. Estimated production turn times are not guaranteed as the vinyl manufacturing production process is delicate and susceptible to manufacturing disruptions. It takes about 30 seconds for the record to press and then cure as water runs through the die to cool off the vinyl. What s more labels.

Manufacturing of custom vinyl pressing ranges from 6 to 7 weeks from start to finish depending on the time of year.